Home to SAHA eggs - For more than 40 years, we are honoured to serve our customers across the region. Arabian Farms is one of the largest and most reliable shell egg producers in the GCC, with roots dating back to 1970 where we started our first farm in the kingdom of Saudi arabia. We've driven to do what's best for our people, our hens, and the environment-all while offering the highest-quality, safest eggs to our customers in the most efficient way possible.

With nearly 1.2 million laying hens (UAE & KSA combined), we produce over 220 million eggs and deliver an average of 40 truckloads of eggs every day. Our farms are located in Dubai (UAE), and Riyadh Saudi Arabia close proximity to the main city, giving us convenient access to our customer base of grocers, food distributors, and food service companies across UAE. We follow a rigorous set of safety standards and processes, allowing us to provide the perfect balance of quality, cost, and guaranteed supply to our customers.

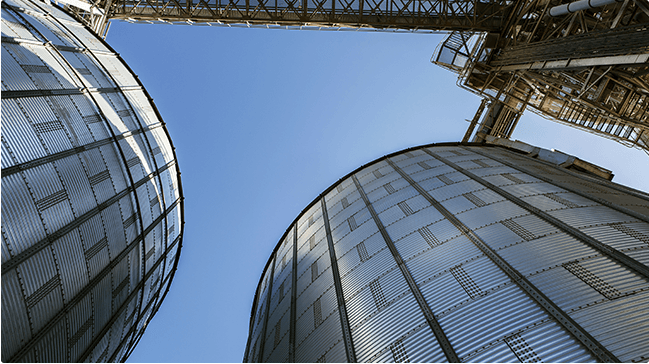

Arabian Farms Dev. Co. Ltd erected Feed Mill in 2000 to become self sufficient and to maintain the quality of the Feed Produced. Feed mill is fully automated with the latest computerized German technology to cope up with the demand in production & quality. Total capacity of the feed mill is 60 Tons per day.

Arabian Farms premix plants with a capacity of 150kg per hour. We have storage silos with capacities of 1500 Tons of Maize & 100 Tones of Soya bean meal on site, and additional capacity of 5000 tons of Maize and 1000 Tones of Soya bean in Warehouse area.

Day old chicks are placed in the rearing house and grown till pullet stage, then the Layers are brought to the layer houses at about 16weeks of age, about 500 yards away.The temperature of the pullet house is warm to make sure that chickens do not bunch together.

At around 16 weeks, chickens are transferred to the layer houses. In these houses, temperature and light are controlled. Cleaning of the houses is one of the most important things to prevent diseases. mortality of the birds are mainly due to bacterial and viral infections, hence strict bio security rules are adopted as a preventive measures to control infection & spread of diseases .

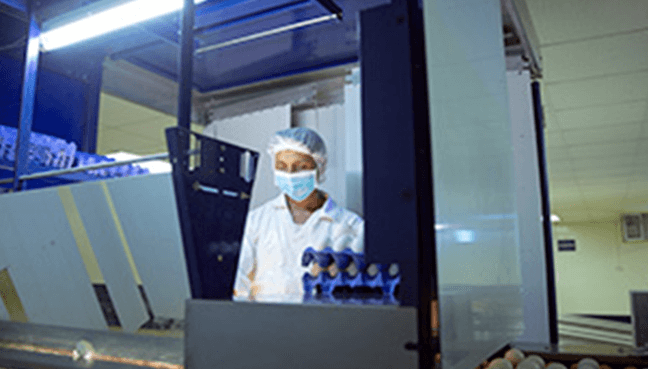

The eggs laid in the layer houses are conveyed to the packing and processing center on daily basis.

In a grading station, eggs are received, candled, weighed & packed into containers with the applicable grade name in an inspected, sanitary environment. Eggs are received and held in a sanitary, refrigerated holding area which is separate from the area where the eggs are graded.

Eggs pass over a bright candling light by means of a conveyor that transports and at the same time, rolls the eggs. The light makes the internal contents of the egg visible allowing a determination of internal defects to be made (i.e. blood spots, meat spots, rot, poor quality yolk, air cell size, etc). By rolling the eggs as they pass over the candling light, the entire outer surface of the egg can be seen by the grader.

The light makes cracks in the shell visible (some cracks are very difficult to see until candled) and also allows dirt, stains, or excessively rough shelled eggs to be seen. By this process, the Candler can determine whether each egg meets the grade requirements for grade AA and A. Defective eggs, leaking eggs and rejects are removed by the Candler and the eggs that meet AA grade requirements proceed to the scales to be weighed.

Eggs are weighed & sorted according to size category for AA and A grade eggs (Jumbo Size, Extra Large Size, Large Size, Medium Size, Small Size and Peewee Size). Each of the sizes has a weight requirement that must be met.

Eggs are packed in containers according to their grade and size. Eggs are stored at an appropriate temperature in the cold storage until they are loaded into a vehicle for transport to the retail location.

All eggs arrive from farm hens which are fed diets that include no hormones, no antibiotics and no animal by-products. We use only Grade AA eggs. To ensure food safety, the process starts with the arrival of clean farm-fresh eggs on sanitized plastic flats

Our patented pasteurization system uses clean, warm water. Eggs are pasteurized to eliminate all harmful bacteria or viruses without cooking the eggs. Our patented technology is regulated standard set by the SFC Korea. Our patented process ensures eggs meet and exceed this requirement without cooking the egg. After pasteurization, eggs move on automated carriers where they receive an optical check that identifies and removes all damaged or cracked eggs. The eggs then are conveyed out of the bath & through an automatic waxing unit which applies a food grade wax protection over the shell. This wax acts as an additional seal to protect the egg from absorption of any cross contaminants that otherwise could pass through the shells thousands of open pores, further ensuring food safety.